Who is Micro?

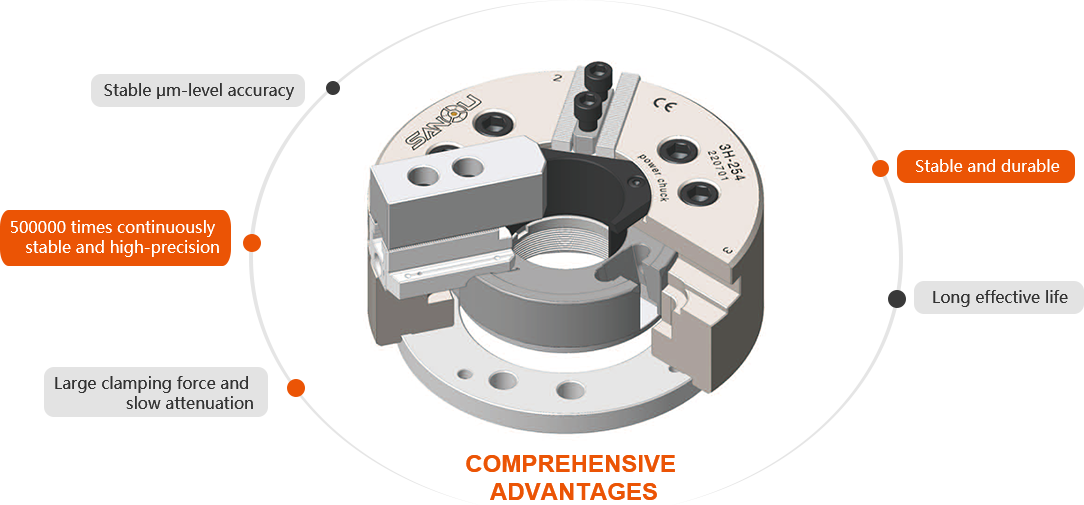

An ultra high precision and excellent continuous performance

New generation hydraulic chuck

Unprecedented precision, the pinnacle of the new generation of dynamic cards

Applicable machinery :

Various types of high-end CNC machine tools

Applicable scenario :

Clamping processing of metal bars, pipes, flanges, and disc profiles

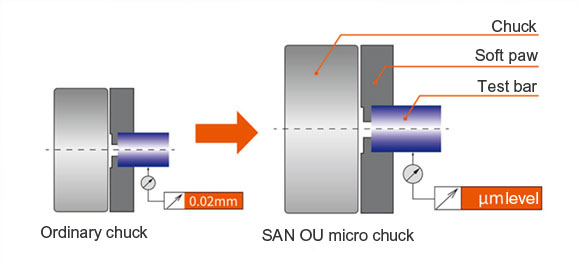

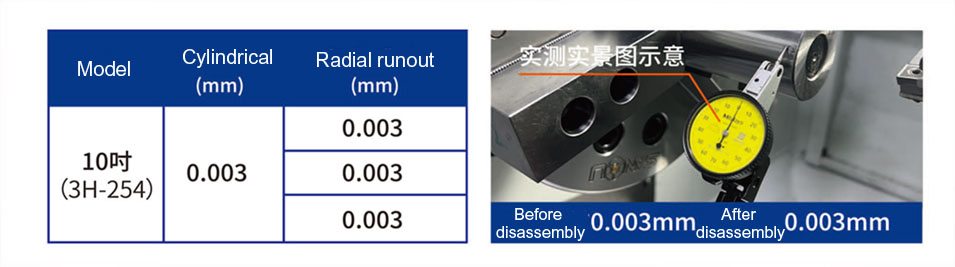

Disruptive μm-level accuracy

The new Micro for precision creates the hydraulic pressure that subverts cognition Chuckaccuracy:

after the jaw is formed, the repeated clamping accuracy is stable at u Level m, which is thetop of high-end manufacturing precision in the world

SAN OU Micro μm-level ultra precision motion card

Promote the clamping accuracy of China to the micrometer level

* The actual measurement accuracy of specific models can reach up to 3μm

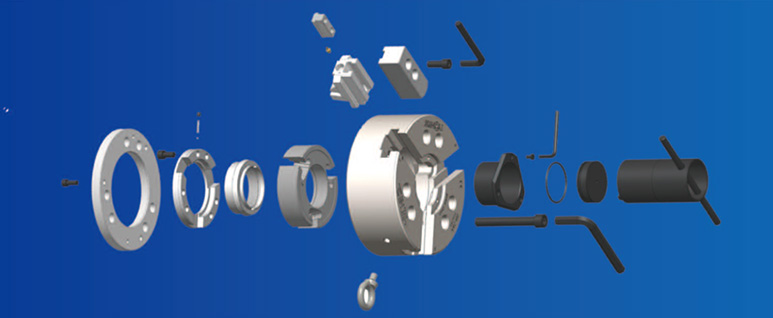

How to ensure μm accuracy

A groundbreaking major upgrade

Laser quenching of key components, one-time clamping and forming

First to use CrNiMo alloy steel

Four times heat treatment process for disc body

Imported heat treatment equipment from Europe

Full closed loop digital factory

Full traceability of one item and one code

MES dynamic quality control

Constant temperature customized grinding

Intelligent tolerance selection

Online probe detection

Parameter Table

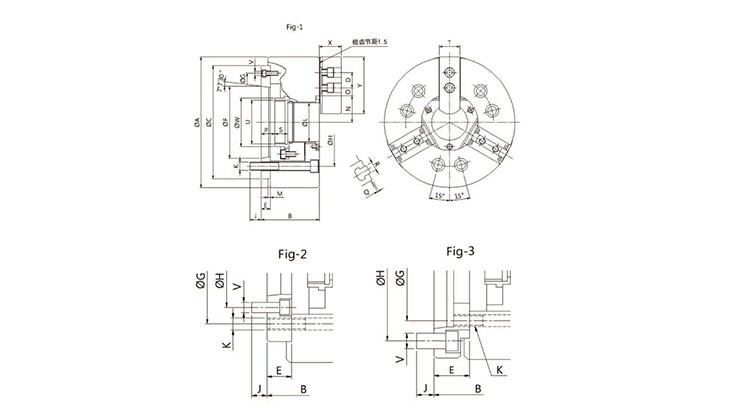

DIMENSION DRAWING

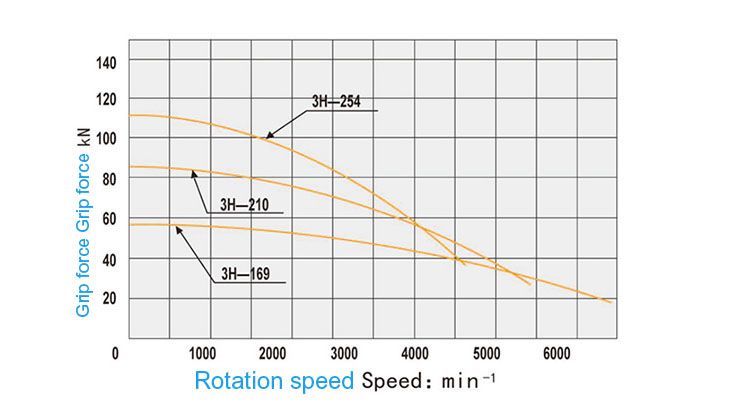

CLAMPING FORCE PERFORMANCE CURVE

DIMENSION TABLE

| Model size | A | B | C | D | E | F | G | H | J | K | L | M | N max. |

O max. |

O min. |

P max. |

P min. |

Q | S | T | U max. |

V | W | X | Y | Reference image |

| 3H-169A4 | 169 | 96 | 140 | 20 | 20 | 63.513 | 104.8 | 82.6 | 16 | 6-M10 | 45 | 5 | 32 | 22.75 | 9.25 | 31 | 19 | 2 | 19 | 31 | M55x2 | 6-M10 | 60 | 37 | 73 | Fig-2 |

| 3H-169A5 | 169 | 91 | 140 | 20 | 15 | 82.563 | 116 | 104.8 | 16 | 6-M10 | 45 | 5 | 32 | 22.75 | 9.25 | 26 | 14 | 2 | 19 | 31 | M55x2 | 3-M6 | 60 | 37 | 73 | Fig-1 |

| 3H-169A6 | 169 | 111 | 140 | 20 | 35 | 106.385 | 104.8 | 1333.4 | 16 | 6-M10 | 45 | 5 | 32 | 22.75 | 9.25 | 46 | 34 | 2 | 19 | 31 | M55x2 | 6-M12 | 60 | 37 | 73 | Fig-3 |

| 3H-210A5 | 210 | 109 | 170 | 25 | 23 | 82.563 | 133.4 | 104.8 | 14 | 6-M12 | 52 | 5 | 39 | 29.75 | 11.75 | 37.5 | 21.5 | 2 | 20.5 | 35 | M60x2 | 6-M10 | 66 | 39 | 95 | Fig-2 |

| 3H-210A6 | 210 | 103 | 170 | 25 | 17 | 106.385 | 150 | 133.4 | 18 | 6-M12 | 52 | 5 | 39 | 29.75 | 11.75 | 31.5 | 15.5 | 2 | 20.5 | 35 | M60x2 | 3-M6 | 66 | 39 | 95 | Fig-1 |

| 3H-210A8 | 210 | 126 | 170 | 25 | 40 | 139.719 | 133.4 | 171.4 | 24 | 6-M12 | 52 | 5 | 39 | 29.75 | 11.75 | 54.5 | 38.5 | 2 | 20.5 | 35 | M60x2 | 6-M16 | 66 | 39 | 95 | Fig-3 |

| 3H-254A6 | 254 | 120 | 220 | 30 | 25 | 106.375 | 171.4 | 133.4 | 18 | 6-M16 | 75 | 5 | 51 | 33.75 | 14.25 | 33.5 | 14.5 | 2 | 25 | 40 | M85x2 | 6-M12 | 94 | 43 | 110 | Fig-2 |

| 3H-254A8 | 254 | 113 | 220 | 30 | 18 | 139.719 | 190 | 171.4 | 24 | 6-M16 | 75 | 5 | 51 | 33.75 | 14.25 | 26.5 | 7.5 | 2 | 25 | 40 | M85x2 | 3-M8 | 94 | 43 | 110 | Fig-1 |

| 3H-254A11 | 254 | 145 | 220 | 30 | 50 | 196.869 | 171.4 | 235 | 28 | 6-M16 | 75 | 5 | 51 | 33.75 | 14.25 | 58.5 | 39.5 | 2 | 25 | 40 | M85x2 | 6-M20 | 94 | 43 | 110 | Fig-3 |

SPECIFICATION SHEET

| Model size | Through-hole diameter (mm) |

Rod stroke (mm) |

Claw stroke diameter (mm) |

Maximum allowable tensile force (KN) |

Maximum speed (r.p.m) |

Weight (kg) |

Moment of inertia (kg.m³) |

Outer diameter clamping range (mm) |

| 3H-169A4 | 45 | 5.5 | 22 | 57 | 6000 | 15.5 | 0.065 | 15-169 |

| 3H-169A5 | 45 | 5.5 | 22 | 57 | 6000 | 14.7 | 0.062 | 15-169 |

| 3H-169A6 | 45 | 5.5 | 22 | 57 | 6000 | 17.3 | 0.073 | 15-169 |

| 3H-210A5 | 52 | 7.4 | 33 | 82 | 5000 | 25.8 | 0.19 | 20-210 |

| 3H-210A6 | 52 | 7.4 | 33 | 82 | 5000 | 25 | 0.184 | 20-210 |

| 3H-210A8 | 52 | 7.4 | 33 | 82 | 5000 | 29.3 | 0.217 | 20-210 |

| 3H-254A6 | 75 | 8.8 | 43 | 111 | 4200 | 41 | 0.37 | 25-254 |

| 3H-254A8 | 75 | 88 | 43 | 111 | 4200 | 38 | 0.34 | 25-254 |

| 3H-254A11 | 75 | 8.8 | 43 | 111 | 4200 | 48.4 | 0.436 | 25-254 |